In a world where technology and innovative solutions shape industries, the term Takoz Reep has gained traction. It might sound unfamiliar to many, but in specific industries, it plays a crucial role. Takoz Reep refers to a particular type of industrial equipment or tool used in mechanical, engineering, or industrial applications. While the name might vary depending on the country or specific use case, its significance remains high in ensuring the proper functioning of machinery and structures.

This article will provide a comprehensive guide to Takoz Reep, delving into its purpose, how it is used across different industries, the materials it is made from, and its benefits. Furthermore, we will address its applications in sectors such as automotive, manufacturing, construction, and more. By the end of this article, you will have a clearer understanding of what Tak-oz Reep is, how it can benefit different processes, and why it’s so essential in certain areas.

1. What is Takoz Reep?

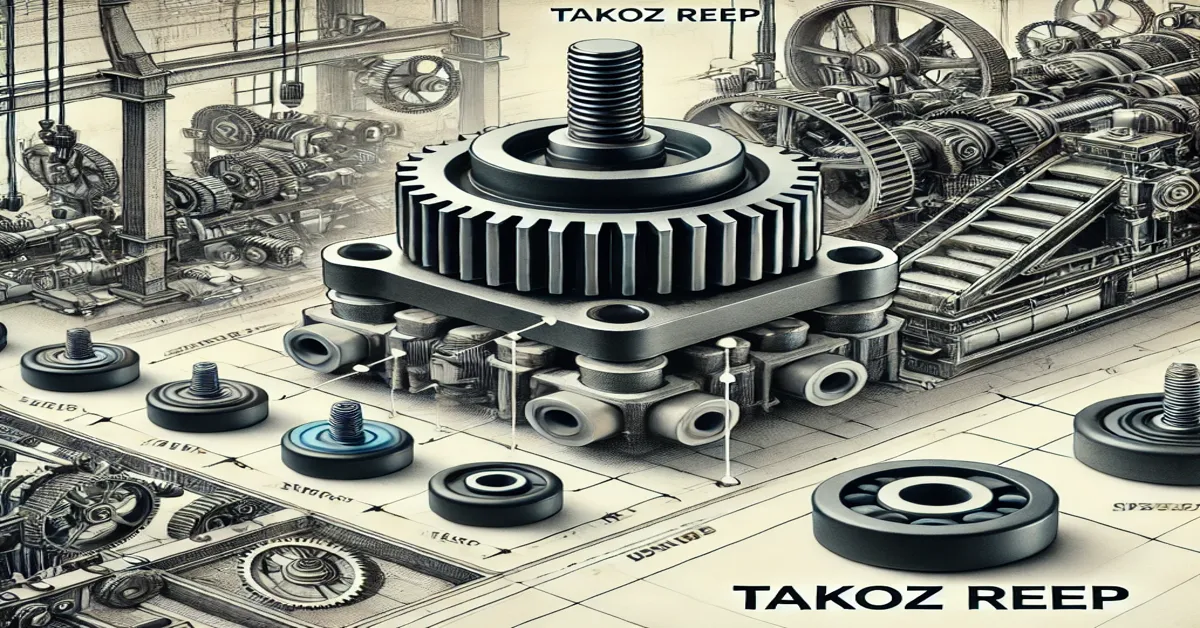

Takoz Reep is a mechanical component often made from durable materials like rubber, polyurethane, or industrial plastics, designed to act as a cushioning, support, or shock-absorbing element in machinery and equipment. The primary purpose of Tak-oz Reep is to dampen vibrations, reduce noise, or protect delicate components from wear and tear by distributing forces evenly across a surface.

1.1 Origins of the Term

The term “takoz” originates from Turkish, where it loosely translates to “block” or “cushion.” This is fitting, as Tak-oz Reep typically serves as a block or buffer between moving parts or as a support for heavy loads. “Reep” could refer to specific industries or applications where this component is commonly used, though its origin may vary across different regions.

1.2 Common Uses

The primary function of Tak-oz Reep is to absorb mechanical stress, prevent damage to machinery, and extend the lifespan of various components. It is commonly used in:

- Automotive Industry: As mounts for engines or transmissions to reduce vibrations and ensure smoother operation.

- Manufacturing: To stabilize heavy machinery and reduce operational noise.

- Construction: As shock absorbers in large structures or equipment, ensuring structural integrity.

- Marine Industry: In shipbuilding, as cushions between moving parts to protect components from the constant stresses of water and waves.

2. Materials Used in Takoz Reep

The effectiveness of Tak-oz Reep largely depends on the materials used in its construction. Depending on the application, different materials offer varying degrees of durability, flexibility, and resilience.

2.1 Rubber

Rubber is one of the most common materials used in the manufacturing of Takoz Reep. Natural or synthetic rubber provides excellent elasticity and is ideal for absorbing vibrations and shocks. Rubber-based Tak-oz Reep components are widely used in automotive applications, where they serve as engine mounts or dampeners to reduce engine noise and vibrations.

2.2 Polyurethane

Polyurethane is another popular material, known for its durability and resistance to chemicals, oils, and wear. Polyurethane Tak-oz Reep components are often found in industrial settings, where they may be subjected to harsh environments or frequent mechanical stress. Polyurethane can also maintain its shape and effectiveness for extended periods, making it a reliable choice for long-term applications.

2.3 Industrial Plastics

In some applications, particularly in lightweight machinery or electronics, industrial plastics are used to create Takoz Reep components. These materials are typically more lightweight than rubber or polyurethane but still provide adequate cushioning and support. Plastic-based Takoz Reep components are ideal for applications where weight reduction is critical.

3. Applications of Takoz Reep

The versatility of Takoz Reep makes it an essential component in many industries. From manufacturing to transportation, Tak-oz Reep helps optimize machinery and ensures the longevity of mechanical components.

3.1 Automotive Industry

In the automotive industry, Takoz Reep plays a critical role in maintaining vehicle performance and comfort. Engine mounts, for example, rely on high-quality Tak-oz Reep components to isolate the engine’s vibrations from the rest of the vehicle, reducing noise and ensuring a smooth ride. These mounts absorb the mechanical shocks generated by the engine’s operation and prevent the vibrations from reaching the vehicle’s chassis.

Other automotive components where Tak-oz Reep is used include suspension systems, transmission mounts, and exhaust systems. In these areas, Takoz Reep helps absorb shocks from the road, protect sensitive components, and improve the overall driving experience.

3.2 Construction and Civil Engineering

In the construction industry, Tak-oz Reep is often used in large structures to ensure stability and integrity. For instance, bridges and buildings are equipped with shock-absorbing pads that help distribute forces and reduce the impact of vibrations caused by heavy machinery or environmental factors such as earthquakes. Tak-oz Reep components in construction also play a vital role in damping mechanical movements in elevators, escalators, and industrial lifts.

3.3 Manufacturing

In manufacturing facilities, machinery often operates at high speeds and generates significant vibrations. These vibrations, if not controlled, can lead to equipment malfunction or breakdowns. Tak-oz Reep components are used to stabilize heavy machinery and absorb the mechanical stresses generated during operation. This reduces wear on the machinery, lowers maintenance costs, and ensures more consistent performance.

3.4 Marine Industry

The marine industry presents unique challenges for mechanical components, as ships and boats are constantly exposed to motion, waves, and changing weather conditions. Tak-oz Reep components are commonly used in shipbuilding to cushion sensitive equipment and protect it from the constant mechanical stress associated with marine environments. These components are particularly critical in areas such as propulsion systems, where they reduce wear and prolong the lifespan of essential parts.

4. Benefits of Using Takoz Reep

The use of Takoz Reep in various industries offers numerous advantages, particularly when it comes to enhancing operational efficiency, extending the lifespan of machinery, and ensuring safety. Some key benefits include:

4.1 Vibration Reduction

One of the primary functions of Tak-oz Reep is to reduce vibrations in mechanical systems. This is particularly important in automotive and industrial applications, where excessive vibrations can cause significant wear and tear on components. By absorbing and dampening these vibrations, Takoz Reep ensures smoother operation and reduces the risk of component failure.

4.2 Noise Reduction

In addition to reducing vibrations, Tak-oz Reep also helps minimize operational noise. This is especially important in automotive applications, where driver and passenger comfort are top priorities. Noise reduction is also beneficial in industrial settings, where quieter machinery can lead to a more comfortable working environment for employees.

4.3 Prolonged Equipment Lifespan

By absorbing mechanical stresses and distributing forces more evenly, Takoz Reep helps reduce the wear and tear on equipment. This, in turn, prolongs the lifespan of machinery and reduces the need for frequent maintenance and repairs. In industries where downtime can result in significant financial losses, the use of Tak-oz Reep can lead to substantial cost savings.

4.4 Improved Safety

Takoz Reep components also contribute to improved safety in mechanical systems. By reducing the risk of component failure due to vibrations or mechanical stress, Tak-oz Reep helps prevent accidents and equipment malfunctions. This is particularly important in high-stakes industries such as construction, where equipment failure can have serious consequences.

5. Installation and Maintenance of Takoz Reep

Proper installation and maintenance are crucial for ensuring the effectiveness and longevity of Tak-oz Reep components. Here are some best practices to follow:

5.1 Installation

The installation of Tak-oz Reep components requires precision to ensure that they are correctly positioned to absorb vibrations and shocks. It’s important to consult the manufacturer’s guidelines for proper installation procedures and to use the appropriate tools. In automotive applications, for example, engine mounts must be installed with the correct torque to ensure optimal performance.

5.2 Regular Inspections

Like any mechanical component, Takoz Reep should be inspected regularly for signs of wear or damage. Over time, these components may become less effective due to exposure to environmental factors, chemical exposure, or mechanical stress. Regular inspections can help identify potential issues before they lead to equipment failure.

5.3 Replacement

While Takoz Reep components are designed to be durable, they may eventually need to be replaced due to wear and tear. It’s important to use high-quality replacement parts from reputable manufacturers to ensure the continued effectiveness of the system. In automotive applications, for example, replacing worn engine mounts with low-quality components can lead to increased vibrations and reduced vehicle performance.

6. Takoz Reep in Emerging Technologies

As technology continues to evolve, so do the applications of Takoz Reep. In emerging industries such as electric vehicles and renewable energy, Takoz Reep components are playing an increasingly important role in ensuring the smooth operation of new technologies.

6.1 Electric Vehicles

In electric vehicles (EVs), Takoz Reep components are used to isolate the vibrations generated by electric motors and powertrains. While EVs produce fewer vibrations than traditional internal combustion engines, the vibrations they do produce can still impact the comfort of the driver and passengers. Takoz Reep helps ensure a smoother, quieter ride by minimizing these vibrations.

6.2 Renewable Energy

In the renewable energy sector, Takoz Reep is used in wind turbines and solar panel systems to absorb mechanical stresses caused by wind, weather, and other environmental factors. By cushioning sensitive components and reducing wear, Takoz Reep helps ensure the long-term efficiency and reliability of renewable energy systems.

Conclusion

Takoz Reep may seem like a small component, but it plays a crucial role in many industries, ensuring the smooth operation of machinery, reducing noise, and prolonging the lifespan of equipment. From automotive applications to construction and marine environments, the versatility of Takoz Reep makes it an indispensable part of modern mechanical systems.

By understanding the purpose, applications, and benefits of Takoz Reep, industries can make informed decisions about incorporating these components into their operations. Whether you’re looking to reduce vibrations in an engine or stabilize heavy machinery, Takoz Reep offers a reliable solution for improving performance and extending the life of your equipment.

FAQs

1. What is the main function of Takoz Reep?

Takoz Reep is primarily used to absorb vibrations, reduce noise, and distribute mechanical stress in machinery and equipment.

2. In which industries is Takoz Reep commonly used?

Takoz Reep is commonly used in the automotive, manufacturing, construction, and marine industries to enhance the performance and lifespan of equipment.

3. What materials are used to make Takoz Reep?

Takoz Reep is typically made from materials such as rubber, polyurethane, or industrial plastics, depending on the application.

4. How does Takoz Reep benefit the automotive industry?

In the automotive industry, Takoz Reep is used as engine mounts and in suspension systems to reduce vibrations, noise, and wear on components.

5. How often should Takoz Reep components be inspected?

Takoz Reep components should be inspected regularly, especially in high-stress environments, to ensure they are functioning properly and to prevent potential equipment failures.

6. Can Takoz Reep be used in electric vehicles?

Yes, Takoz Reep is used in electric vehicles to minimize vibrations from electric motors and powertrains, improving comfort and performance.

4o